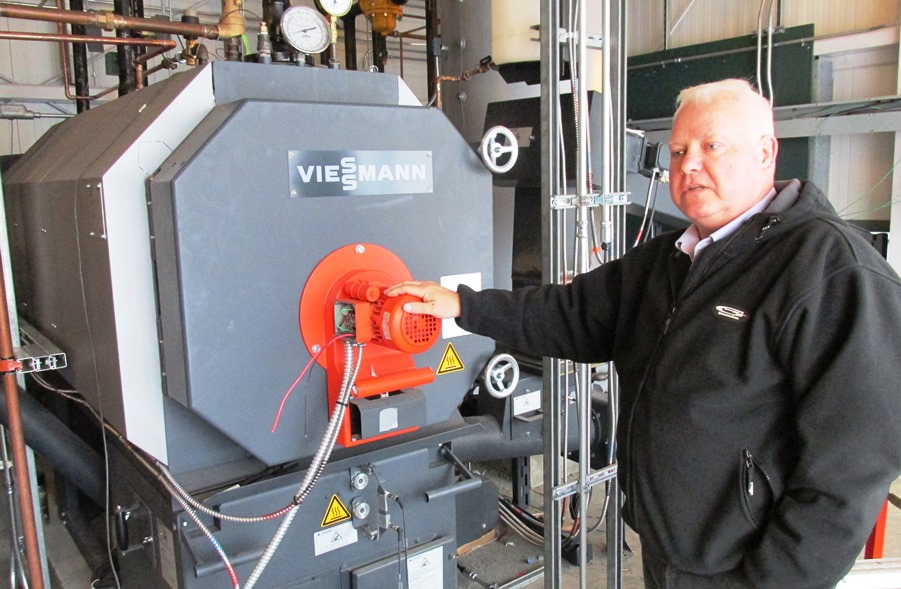

Airport Manager Mike Carney stands next to the Ketchikan International Airport’s new biomass wood-pellet boiler last summer. (File photo by Leila Kheiry)

It’s great to talk about biomass as a renewable energy source, but how does it work in real-world situations? During last week’s Alaska Wood Energy Conference in Ketchikan, participants heard three “case studies” from communities in Alaska that have invested in biomass.

Audio PlayerGalena is a small village about 300 miles west of Fairbanks. It gets cold there in the winter – like negative-40 cold – so heat is pretty important.

Their big industry is education. Galena is home to a regional boarding school on the site of a former U.S. Air Force base. Tim Kalke is a teacher at that school, and worked on plans to improve the heating system for the 14-building Galena Interior Learning Academy.

“Heat to these buildings was distributed through steam,” he said. “They had several steam boilers that took the load. Very inefficient, and very old. Annual consumption of fuel for that system was about 230,000 gallons.”

Kalke said getting a new wood-chip boiler was essential for the community to continue operating the school economically, and there were many steps from start to finish.

For example, they needed a forest inventory to make sure they had enough wood fuel. They had to redo their entire water pipe system because, it turned out, one of the reasons the old steam boilers were so inefficient is the heat from that system kept the water pipes from freezing.

Then they had to convert the old steam boilers to hot water boilers – they supplement the wood chip boiler as needed. And, they had to figure out a system for harvesting, drying, chipping and storing wood.

The new system has been in place for a season, and there were some kinks to work out when they first cranked it up. But, Kalke said, so far it’s displaced 52,000 gallons of fuel oil.

The Ketchikan International Airport’s new biomass boiler building is seen last summer. The pellet silo on the right holds up to 30 tons. (File photo by Leila Kheiry)

Ketchikan International Airport was another case study presented for the conference. Airport Manager Mike Carney said he first looked into replacing the airport’s oil-fired boilers with another oil system.

“Interesting enough, I probably got a higher bid to replace my oil-fired boilers with another oil system than I ended up with with biomass,” he said.

Carney somewhat jokingly thanked everyone who made mistakes installing their own biomass systems. He said he learned from those mistakes. One big lesson was to hire biomass engineers with a proven track record of successfully installed systems.

“And when I say successful systems, I don’t go to the bean counters or to the contracting officer to find out if their system is successful. I go to the guy who pushes the buttons,” he said.

Ketchikan airport’s biomass boiler was installed and operational in summer of 2016. It was almost entirely grant funded, and saves the airport an estimated 40 percent on fuel costs. It also uses locally produced wood pellets.

Tanana City Manager Jeff Weltzin talked about the project his community installed to heat the city’s public buildings. He said one of the city’s goals is reducing the need for imported fuel as much as possible.

To that end, they connected their old oil-fired boilers to the new biomass system, cutting their oil use significantly, even  during this last, extremely cold winter.

during this last, extremely cold winter.

“We estimate this last winter, we displaced 40,000-50,000 gallons of fuel, so even at $3 a gallon, that’s $120,000 to $150,000 of savings,” he said.

Weltzin said the wood supply surrounding Tanana is good for many decades, and they expect they also can use standing-dead trees left after a massive wildfire came through the area a couple years ago.

“We found that standing dead in the Interior has a longevity of 30 years,” he said. “We have tens of thousands of acres of standing dead around the community. Our goal is to do a harvest plan and ultimately try to replant, regenerate, with some high-value trees.”

Along with hiring local residents to harvest trees for the biomass boilers, Weltzin said reforestation is another potential economic-development investment for the community.

They’re also working toward a biomass-heated greenhouse for local students to operate – yet another sustainable investment connected to wood energy.